Operating an LVDT in an evacuated environment requires some special considerations. Through packaging variations or mounting considerations, the integrity of our standard LVDT’s characteristics can be preserved. In order to select the most appropriate version, the differences between operation in a normal environment and a vacuum must be understood.

Heat Dissipation

Under normal atmospheric pressure, the majority of the heat generated by the LVDT is dissipated through convection and conduction. In a vacuum, the lack of atmosphere prevents cooling through convection. The device will still conduct thermal energy to objects in contact with it but they have to in turn dissipate the heat. The buildup of heat causes inaccurate measurements and the possible thermal overload of the LVDT.

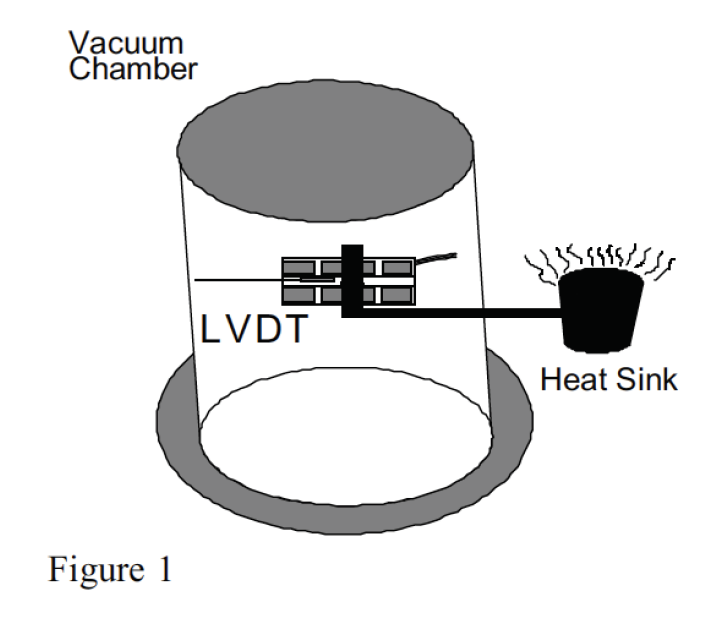

In order to provide sufficient cooling for the device, different procedures can be utilized. One method is to connect the housing of the LVDT to some object outside of the vacuum. The connective object in the vacuum will act as a thermal conductor between the LVDT and the outside environment. To keep the temperature of the unit to a minimum, a low excitation voltage is recommended. Reference Figure 1.

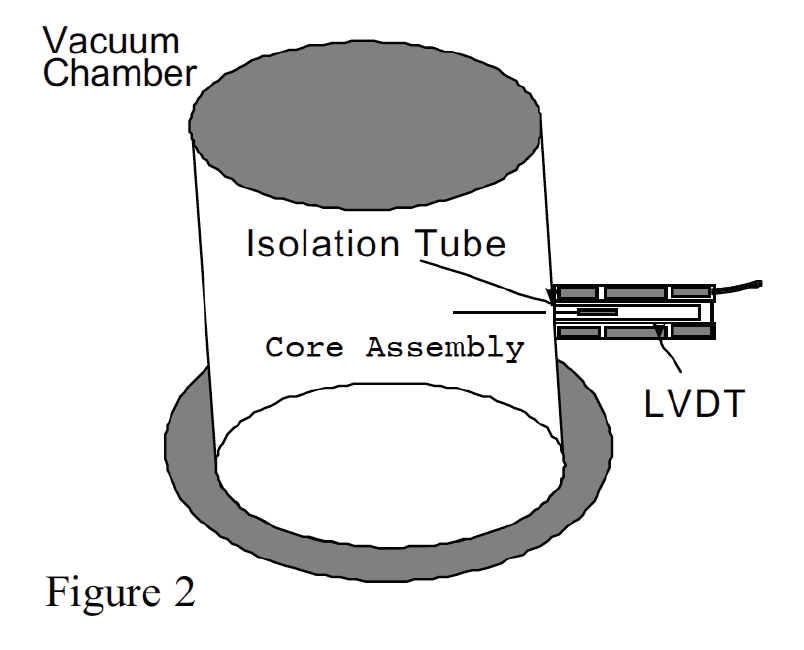

A second method is to mount the LVDT in an isolation tube outside the vacuum. This allows the housing to remain in a normal atmosphere, eliminating the need for thermal dissipation strategies. Reference Figure 2.

Outgassing

The other concern associated with vacuum operations is outgassing. Under normal atmospheric pressures, materials that behave as stable liquids or solids remain so as long as the environment is not changed drastically. When the atmosphere starts to depressurize, pockets of gas and air that are trapped in the materials will escape. This effect takes place in the epoxy, adhesives, and silicon rubber that are used in a standard transducer. Outgassing introduces a new gaseous volume to the atmosphere you are trying to depressurize, reducing the integrity of the vacuum. Another consideration is the effect of the escaping gas on other components in the environment. Epoxies emit volatile gas, and although not corrosive, it may coat other elements, like a camera lens or sensitive silicon materials. These effects must be considered when setting up such an environment.

Because there may be a partial seal on between the housing and the coil on the LVDT, the outgassing that occurs in the unit may become trapped and released over a period of time. The solution TRANS-TEK uses to prevent this is to vent the housings to allow unrestricted escaping of the gaseous material. To reduce the amount of outgassing that takes place, the silicon rubber and other materials used in DC-DC units are replaced with more suitable material.